Big Red here with a question from "Terri Irwin"...

So, TAKE FIVE!

Terri asks,

“Big Red, how did the Riddell football type head band get transformed into the adjustable type?”

Great hearing from you Terri,

Good ole fashioned entrepreneurial spirit and unhindered creativity.

When production began on the M-1 helmet body, experimentation and innovation were occurring simultaneously, the plastic liner was no different.

The Army was under no delusions when they accepted the pressed paper liner knowing full well that it would not hold up to field use, specifically moisture, but the M-1 helmet is rather useless without a liner so the Army approved this pressed paper assembly followed by whatever best liner solution they developed, as it was developed.

The Responsibility for the development and procurement of the liner ultimately fell to the Chicago Quartermaster Depot. Beginning in October 1941, meetings involving members representing various branches of the QMC as well as all prime and sub-contracted companies involved in the manufacture of the liner, were held to discuss the current state of development.

Explanations of what the Army considered faulty with the design were expressed and the suppliers were asked to work out their best solutions to these problems and present them as samples.

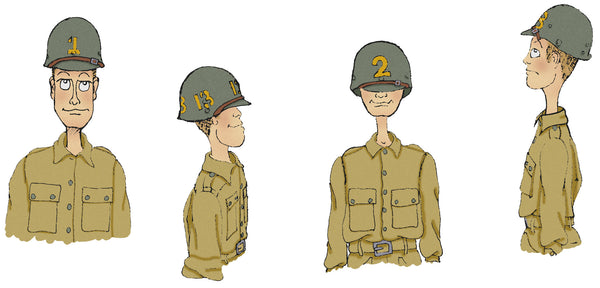

Of all the liner assemblies’ faults in need for improvement, the Army noted that the requirement for 13 sizes of head band necessary to create a proper fit was the most egregious.

In addition, the six sets of snaps necessary for attaching the band to the suspension caused painful discomfort to the wearer. The Army wanted desperately to replace the current 13 sized bands with a single adjustable design.

Of the various samples submitted, to the Research and Development Branch of the Office of The Quartermaster General, Garnett C. Skinner, manager of the Scholl Manufacturing Company, devised the sample the Army chose. Mr. Skinner’s design was a partially leather clad strip of webbing laid out like a belt with a simple wire bar buckle at one end.

This allowed for the end of the webbing to pass through the bar buckle, and be pushed back through, to enable adjustment to various sized heads.

The primary reason the Scholl Company solution was chosen over the others, was their use of a hardware clip they had devised which allowed the band to be sized then clipped directly to the suspension solving not only the question of adjustability but the discomfort issue of the modified Riddell snap system.

Big Red Says!

FIVE'S OVER - MOVE OUT!

You are correct Jim. Liner contractors that still had Rayon used it up first while those that did not switched to the new cotton webbing from the start.

Another good read.

I can see why they eliminated the fitted headband, it must have been a disaster for the Quartermaster.

a question though, when they switched to the adjustable headband was it about the same time they moved away from the rayon liner webbing?

Leave a comment